Government’s plan to restrict the importation of cement, a move which comes into effect at the start of October, has been welcomed with open hearts by local cement manufacturers.

In a bid to control the influx of cement products from outside Botswana, while at the same time giving locals the chance to participate in the value chain, cement will only be allowed into the country in 1, 000kg quantities and nothing less.

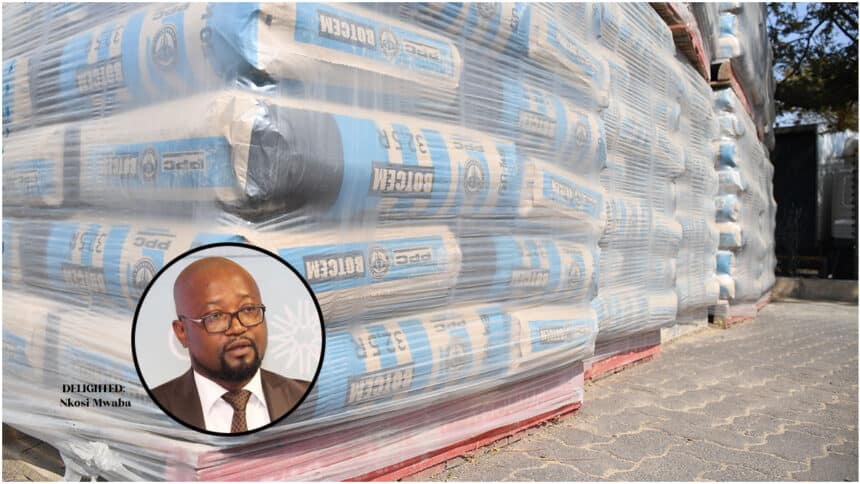

Botswana Cement Manufacturers Association’s (BCMA) delighted Chairman, Nkosi Mwaba, revealed this was something they have been calling for, for the longest time.

“After extensive consultations between the industry and the government, we are pleased that this decision was made. With a protective regime and similar shifts in legislation, we have often seen two things happening: one is the strengthening and growth of the current and existing players in the market where we will see increased investment in their respective installed capacity, additional shifts and strategic repositioning of local businesses in response to the legislative change. Secondly, the cement industry in Botswana will become more attractive to foreign direct investment as the new regulations give a sense of comfort and predictability to foreign players,” the elated Mwaba told Voice Money.

The market demand for cement in Botswana currently sits at 600, 000 metric tonnes per annum.

Excluding the supply of bulk loads, which are used for ready-mix and construction projects which makes up 25 percent of national demand, local producers are expected to produce and supply at least 450, 000mt of pre-packed cement every year.

According to Mwaba, the current capacity within Botswana stands at 480, 000mt amongst the three existing producers: Kago Phepa, Cheetah Cement and PPC Botswana.

However, if all goes to plan, this will increase by 20 percent come September, before the restrictions ‘go live’.

“Naturally, we do expect push back and resistance from some of our stakeholders, some with genuine concerns about supply and demand of product in Botswana. We take those concerns seriously and have already begun extensive consultation with our members and the supply chain to address the same. Our members resolved to adjust and ready their production levels in anticipation of the anticipated increased demand on local pre-packed output. There were various commitments made, including operational efficiencies and increased production hours going up from single to three-shift systems as an example, members have committed to investing in increased capacity and improved logistical efficiencies ahead of implementation date,” explained Mwaba.

The BCMA boss is confident local manufacturers have the capability to produce well over 500, 000mt of pre packed cement.

To ensure this happens, Mwaba revealed they engaged Botswana Railways for bulk deliveries of product and raw material and Morupule power stations for the consistent supply of fly ash.

“We are in the process of engaging trucking associations for their readiness and support, customs and excise through common entry ports for awareness and readiness and other players within the value chain. The increase in capacity is also in anticipation of the increase in construction projects expected over the next three years in Botswana. These are firm commitments made to ease market fears and give assurances to consumers,” declared Mwaba.